DIGITAL TWIN

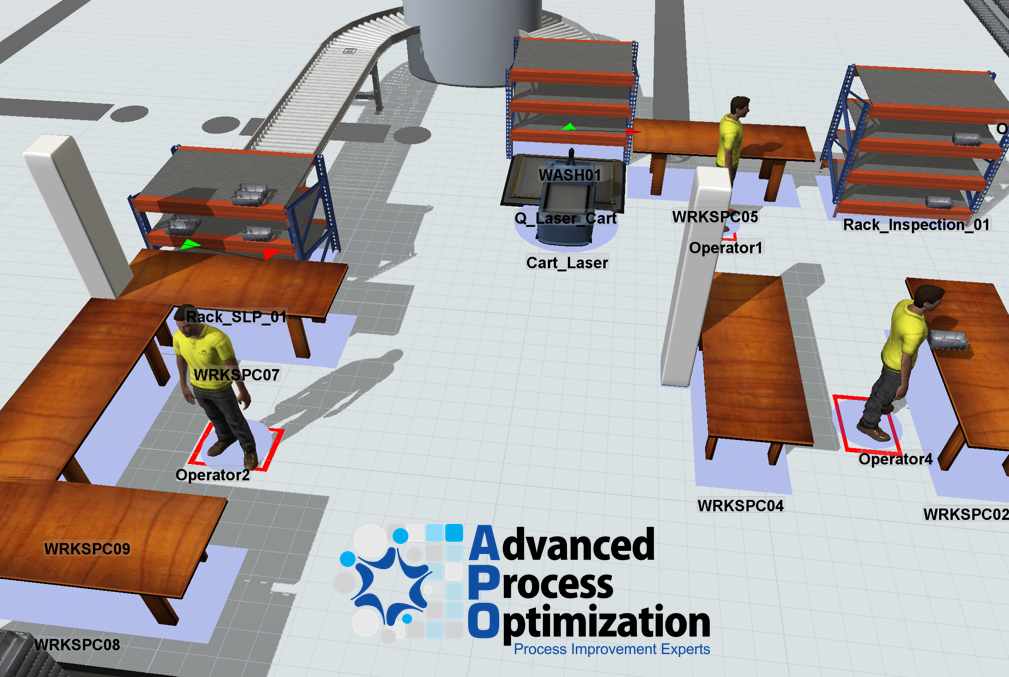

A “Digital Twin” is created using Simulation Modeling software. APO has used several software packages in the past and now uses FlexSim as our primary tool. There are many benefits to using this technique such as:

- Minimizing & Mitigating Risk

- Evaluating Process Flows

- What-if Analysis

- Process Optimization

- Process Visualization

- Effect of New Product Introduction

- Cost Analysis

- Carbon Footprint Analysis and Reduction

- Pre-Implementation Design Testing

WHEN TO USE SIMULATION MODELING

Ask yourself these questions:

Simulation + LSS Whitepaper

How Advanced Process Optimization, Inc. used simulation modeling in concert with traditional Lean techniques to deliver an advanced process improvement solution

The Client: A rail-bearing manufacturer, and an industry world leader in friction reduction and drive systems.

The Task: Evaluate the process performance of a rail system bearing reconditioning and assembly facility — with the goal of identifying opportunities to improve throughput.

The Solution: In this improvement project, Advanced Process Optimization, Inc. (APO) married traditional Lean Six Sigma (LSS) techniques with simulation modeling using FlexSim® (FlexSim Software Products, Inc.). The experience showed how simulation modeling can reinforce LSS by adding powerful analytical capabilities, eye-opening visualization, and by stimulating new ideas and building ownership while vetting…

Simulation Success Stories

STEEL CAPITAL EQUIPMENT PROCESS SIMULATION MODELING

Learn how Advanced Process Optimization helped a Steel Equipment engineering and manufacturing company validate their engineering design using techniques that go way beyond Design for Six Sigma (DFSS). We gave the sales team something to work too!

FIREARMS MANUFACTURER GREENFIELD PLANT DESIGN

Learn how Advanced Process Optimization designed the new manufacturing facility layout, material flow, and machine requirements for a high-end firearms manufacturer. What is just Lean Manufacturing, or something more?

HIDDEN CAPACITY DRIVING REVENUE GENERATION

A company that tests equipment for various industries including Aerospace & Defense, Spaceflight, and Telecom has been losing market share due underpricing by smaller niche competitors.

LEAD TIME AND INVENTORY REDUCTION

We reduced the Purchase Order Lead Time by about 25 days (39%) and eliminated about $4,500,000 in WIP inventory in 10 months. We accomplished this in two weeks of billable time. Now that is real return on investment.